Nanooze Blog

Light-Emitting Shirts

Although the technology is fairly new, Philips Research has made amazing progress in integrating Lumalive fabrics into garments that can be worn by people. Lumalive fabrics are made of flexible arrays of colored light-emitting diodes (LEDs) integrated into the fabric so that the fabric remains soft and flexible. With these fabrics, it’s possible to create clothing that carry dynamic messages, graphics, or multicolored surfaces. These fabrics can even be used in drapes, cushions, or sofa coverings!

Jackets, featuring 200 mm x 200 mm panels of Lumalive fabrics, are comfortable to wear and can light up to display vivid colored patterns, logos, short text messages, or even full color animations. For the parts that can’t be easily washed – such as the batteries and control electronics, Philips Research has designed a simple disconnect-reconnect socket into the garment. Even the light emitting layer of the jacket can be easily removed and refitted.

Click on the movie screen on the right to watch a Youtube clip of these amazing LED shirts!

Source: Philips illuminates IFA 2006 with production-ready Lumalive textile garments

Nanowire Paper

Like your everyday notebook paper, this new type of nanowire-paper can be folded, cut, bent, and used as a filter. But unlike normal paper, it is chemically inert, robust, and can be heated up to 700 degrees Celsius. Researchers at the University of Arkansas have created long nanowires out of titanium dioxide connected by free-standing membranes. The resulting material is white, resembles regular paper, and has a variety of potential applications, such as armor, flame-retardant fabric, bacteria filters, controlled drug release, decomposition of pollutants, and chemical warfare agents.

Like your everyday notebook paper, this new type of nanowire-paper can be folded, cut, bent, and used as a filter. But unlike normal paper, it is chemically inert, robust, and can be heated up to 700 degrees Celsius. Researchers at the University of Arkansas have created long nanowires out of titanium dioxide connected by free-standing membranes. The resulting material is white, resembles regular paper, and has a variety of potential applications, such as armor, flame-retardant fabric, bacteria filters, controlled drug release, decomposition of pollutants, and chemical warfare agents.

Source:Nanowire-Paper Offers Strength, Flexibility

Climb Like A Gecko

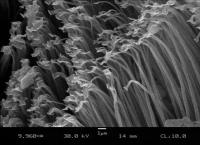

Geckos have remarkable hairs on their feet that allow them to hang single-toed from sheer walls and scamper along ceilings. Researchers and engineers at the University of California, Berkeley have created an array of synthetic microfibers to mimic this natural phenomenon. Made of high-friction materials that prevent sliding under high loads, these polypropylene fibers can hold a quarter to a glass slide that is tilted at an 80 degree angle. These fibers are highly packed, with approximately 42 million fibers per square centimeter, each fiber measuring 20 micrometers in length and 0.6 micrometers in diameter. One micron is one-thousandth of a millimeter. However, these fibers do not exhibit adhesion, which means that even if they make micro-fiber suits, people shouldn’t try any Spiderman stunts!

Geckos have remarkable hairs on their feet that allow them to hang single-toed from sheer walls and scamper along ceilings. Researchers and engineers at the University of California, Berkeley have created an array of synthetic microfibers to mimic this natural phenomenon. Made of high-friction materials that prevent sliding under high loads, these polypropylene fibers can hold a quarter to a glass slide that is tilted at an 80 degree angle. These fibers are highly packed, with approximately 42 million fibers per square centimeter, each fiber measuring 20 micrometers in length and 0.6 micrometers in diameter. One micron is one-thousandth of a millimeter. However, these fibers do not exhibit adhesion, which means that even if they make micro-fiber suits, people shouldn’t try any Spiderman stunts!

Source:Engineers create gecko-inspired, high-friction micro-fibers

The Sharpest Tip

Forget the popular phrase, “sharp as a tack.” Researchers at the University of Alberta have revised the expression to be, “sharp as a single atom tip formed by chemically assisted spatially controlled field evaporation.” It might not roll off the tongue as easily, but it would be far more accurate. Scientists at the National Institute of Nanotechnology (NINT) at the University of Alberta have used a unique process to make a small sharp pyramid of tungsten atoms covered with a one-atom-thick coating of nitrogen, stable enough to withstand about 900 degrees Celsius. These super-sharp tips are necessary for making contacts with metals or semiconductors. Ultrafine tips are also useful in helping researchers manipulate and examine atoms, molecules, and other small particles. These tips, in particular, are so sharp that they work as excellent emitter of electron beams, and can potentially be used to improve the current electron microscopes

Forget the popular phrase, “sharp as a tack.” Researchers at the University of Alberta have revised the expression to be, “sharp as a single atom tip formed by chemically assisted spatially controlled field evaporation.” It might not roll off the tongue as easily, but it would be far more accurate. Scientists at the National Institute of Nanotechnology (NINT) at the University of Alberta have used a unique process to make a small sharp pyramid of tungsten atoms covered with a one-atom-thick coating of nitrogen, stable enough to withstand about 900 degrees Celsius. These super-sharp tips are necessary for making contacts with metals or semiconductors. Ultrafine tips are also useful in helping researchers manipulate and examine atoms, molecules, and other small particles. These tips, in particular, are so sharp that they work as excellent emitter of electron beams, and can potentially be used to improve the current electron microscopes

Source:University of Alberta Nanotechnology Researchers Create Sharpest Tip Ever Known

Nanotube Printer Ink

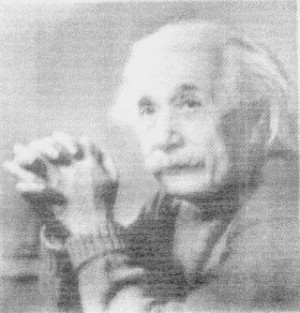

The picture on the right of Albert Einstein may not look remarkable, but it’s actually an electrically conductive image printed on regular printer paper with carbon nanotube ink. Using an off-the-shelf inkjet printer, scientists have developed an easy technique to print patterns of carbon nanotubes on paper and plastic surfaces. Carbon nanotubes have fascinated researchers with their high strength, low weight, and excellent conductivity since their discovery in 1991. Most current techniques for patterning nanotubes have required the use of expensive equipment, but this new inkjet printer technique may allow nanotubes to be easily deposited on various surfaces. Since nanotubes are good conductors, the printed images are able to conduct electricity, which opens up new possibilities in the field of flexible electronics. Some scientists are thinking of printing electronics onto cloth, allowing people to actually “wear” a battery or a cell phone!

The picture on the right of Albert Einstein may not look remarkable, but it’s actually an electrically conductive image printed on regular printer paper with carbon nanotube ink. Using an off-the-shelf inkjet printer, scientists have developed an easy technique to print patterns of carbon nanotubes on paper and plastic surfaces. Carbon nanotubes have fascinated researchers with their high strength, low weight, and excellent conductivity since their discovery in 1991. Most current techniques for patterning nanotubes have required the use of expensive equipment, but this new inkjet printer technique may allow nanotubes to be easily deposited on various surfaces. Since nanotubes are good conductors, the printed images are able to conduct electricity, which opens up new possibilities in the field of flexible electronics. Some scientists are thinking of printing electronics onto cloth, allowing people to actually “wear” a battery or a cell phone!

Source:Nanotube ink: Desktop printing of carbon nanotube patterns

Tiny Bacteria-Powered Motors

So, you’ve probably seen horses pulling carraiges or dogs hauling a sled through snow, but have you ever seen motors run by bacteria? This newest use of animal power requires a microscope to see the little critters in action. Researchers in Japan have found a way to use crawling bacteria to power a rotating micromotor. The rotor is made of silicon dioxide and powered by a strain of bacteria called Mycoplasma mobile, which are pear-shaped and just 1 micrometer long. When placed on a mat made of certain proteins, these bacteria crawl around. Scientists coat the groove underneath the rotor with a special protien that attracts the bacteria and then cover the rotor with another type of protein. The bacteria is coated with a substance that is attracted to the protein on the rotor and let loose into the grooves. The bacteria are encoraged to move in just one direction around the circle, and their movements cause them to brush against the rotor, causing it to turn. The bacteria movement is slow and the rotor spins only twice as fast as the second hand on a watch. However, with more bacteria, the rotor might be able to spin 100 times faster. Using bacteria to power machines has great potential in the future of “living machines” since bacteria run on simple sugars for fuel and can easily replicate and repair themselves.

Source:Bacteria Power a Tiny Motor

Nano Bed Sheets

At your local JC Penny store, you can now purchase wrinkle-free 100% cotton performance sheets that make use of nanotechnology to engineer materials to perform special functions. Traditional coatings on bed sheets make them feel stuff and clog the weave of the fabric, making it harder for the skin to breath at night. Nano-Tex’s Coolest Comfort fabric uses nano-sized treatments that are small enough to attach to the fabric fibers without clogging the weave. As a result, the fabric is able to draw moisture away from the skin and help balance body temperature so that you can snuggle up and get a good night’s sleep!

At your local JC Penny store, you can now purchase wrinkle-free 100% cotton performance sheets that make use of nanotechnology to engineer materials to perform special functions. Traditional coatings on bed sheets make them feel stuff and clog the weave of the fabric, making it harder for the skin to breath at night. Nano-Tex’s Coolest Comfort fabric uses nano-sized treatments that are small enough to attach to the fabric fibers without clogging the weave. As a result, the fabric is able to draw moisture away from the skin and help balance body temperature so that you can snuggle up and get a good night’s sleep!

Source:U.S. Department Store Chain Now Offers Nano Bed Sheets in Hundreds of Locations

Tour de France à la Carbon Nanotubes

If Floyd Landis, leader of the Phonak team, wins the three-week Tour de France, a popular bike race, it will be a victory for nanotechnology too! For the race, Landis is riding a bike that has been enhanced with carbon nanotubes. Since carbon nanotubes sprinkled into materials can help reduce weight and provide additional strength, the bikes ridden by the Phonak team have nanotubes swirled into the frame. As a result, the frame of the BMC Pro Machine SLC 01 weighs less than a kilogram (that’s 2.2 pounds!), making it one of the lightest frames in the race. Nanotubes were developed in the early ’90s, and are essentially cylinders of carbon atoms arranged in hexagons that look like spools of chicken wire under a microscope. Their unique structure gives the tubes special properties. For example, nanotubes are several times stronger than steel and much, much lighter. Nanotubes can also conduct electricity, act as insulators, and transfer light signals. But currently, the main use of carbon nanotubes is to strengthen and reduce weight in retail items, such as cars, golf clubs, tennis rackets, and bikes!

If Floyd Landis, leader of the Phonak team, wins the three-week Tour de France, a popular bike race, it will be a victory for nanotechnology too! For the race, Landis is riding a bike that has been enhanced with carbon nanotubes. Since carbon nanotubes sprinkled into materials can help reduce weight and provide additional strength, the bikes ridden by the Phonak team have nanotubes swirled into the frame. As a result, the frame of the BMC Pro Machine SLC 01 weighs less than a kilogram (that’s 2.2 pounds!), making it one of the lightest frames in the race. Nanotubes were developed in the early ’90s, and are essentially cylinders of carbon atoms arranged in hexagons that look like spools of chicken wire under a microscope. Their unique structure gives the tubes special properties. For example, nanotubes are several times stronger than steel and much, much lighter. Nanotubes can also conduct electricity, act as insulators, and transfer light signals. But currently, the main use of carbon nanotubes is to strengthen and reduce weight in retail items, such as cars, golf clubs, tennis rackets, and bikes!

Source:Carbon nanotubes enter Tour de France

Photolithography – Smaller and Smaller

Earlier this year, researchers at IBM created the smallest, high-quality features ever made with the main-line photolithography technique – 193nm deep UV illumination. This technology is currently used to “print” circuits onto semiconductor chips. Similar to silk-screening, except using light instead of paint or ink, photolithography can transfer various designs and patterns onto a silicon wafer by shining laser light through a shadow mask onto a photosensitive photoresist material that coats the silicon wafer. As shown in the picture on the left, the ridges formed by this technique are only 29.9 nanometers wide, which is less than one-third the size of the current 90-nanometer features (on the right) that are currently used in mass production. Over the years, improvements in the photolithography process have led to the continual shrinking of circuits and semiconductor chips, which in turn leads to smaller, faster, and cheaper electronics.

Earlier this year, researchers at IBM created the smallest, high-quality features ever made with the main-line photolithography technique – 193nm deep UV illumination. This technology is currently used to “print” circuits onto semiconductor chips. Similar to silk-screening, except using light instead of paint or ink, photolithography can transfer various designs and patterns onto a silicon wafer by shining laser light through a shadow mask onto a photosensitive photoresist material that coats the silicon wafer. As shown in the picture on the left, the ridges formed by this technique are only 29.9 nanometers wide, which is less than one-third the size of the current 90-nanometer features (on the right) that are currently used in mass production. Over the years, improvements in the photolithography process have led to the continual shrinking of circuits and semiconductor chips, which in turn leads to smaller, faster, and cheaper electronics.

Source:IBM Research demonstrates path for extending current chip-making technique

Liquid Armor

Led by researchers at the University of Delaware and at the U.S. Army Research Lab, a new “liquid armor” is being developed to protect against life-threatening injuries. The liquid is made up of a mixture of hard nanoparticles that flows under normal conditions, but stiffens and behaves like a solid under impact. The impact causes the nanoparticles to form tiny clusters inside to fluid to prevent things from penetrating through the armor. By treating fabrics with this liquid, a body armor could be developed to prevent bullets, knife stabs, or shrapnel from harming the body. There are also a number of civilian applications, such as protection against car crashes or making tires sturdier.

Led by researchers at the University of Delaware and at the U.S. Army Research Lab, a new “liquid armor” is being developed to protect against life-threatening injuries. The liquid is made up of a mixture of hard nanoparticles that flows under normal conditions, but stiffens and behaves like a solid under impact. The impact causes the nanoparticles to form tiny clusters inside to fluid to prevent things from penetrating through the armor. By treating fabrics with this liquid, a body armor could be developed to prevent bullets, knife stabs, or shrapnel from harming the body. There are also a number of civilian applications, such as protection against car crashes or making tires sturdier.

Source:Liquid Armor

Nano Corks for Nano Test Tubes

Though chemotherapy works against many cancers, the side effects, such as nausea, temporary hair loss, and blood disease, can be huge. Looking to deliver cancer drugs only to cancer cells, scientists from the University of Florida have found a way to fill tiny carbon nanotubes with drugs and “cork” the tubes. After injection into the body, these tiny test tubes will seek out diseased cells, uncork, and deliver the drugs to the right place. Each tube is about 80 nanometers in diameter and can hold 5 million drug molecules, which definitely packs a punch.

Though chemotherapy works against many cancers, the side effects, such as nausea, temporary hair loss, and blood disease, can be huge. Looking to deliver cancer drugs only to cancer cells, scientists from the University of Florida have found a way to fill tiny carbon nanotubes with drugs and “cork” the tubes. After injection into the body, these tiny test tubes will seek out diseased cells, uncork, and deliver the drugs to the right place. Each tube is about 80 nanometers in diameter and can hold 5 million drug molecules, which definitely packs a punch.

Source:World’s tiniest test tubes get teensiest corks

Nano Paint

Well we have all been places where the cell phone don’t work. What a pain!. But maybe there are times when people shouldn’t be allowed to use their cell phones, for example, at the movie theatres or during class lectures. NaturalNano, a Rochester, N.Y. based company, is developing high-tech paint that can effectively block out unwanted cell phone signals. Based on nanotechnology, the paint uses particles of copper inserted into “nanotubes”, which are then blended into the paint to deflect radio signals. The company claims that it can filter out unwanted signals, while allowing certain transmissions, such as the emergency notification of surgery for a brain surgeon, to proceed as normal.

Well we have all been places where the cell phone don’t work. What a pain!. But maybe there are times when people shouldn’t be allowed to use their cell phones, for example, at the movie theatres or during class lectures. NaturalNano, a Rochester, N.Y. based company, is developing high-tech paint that can effectively block out unwanted cell phone signals. Based on nanotechnology, the paint uses particles of copper inserted into “nanotubes”, which are then blended into the paint to deflect radio signals. The company claims that it can filter out unwanted signals, while allowing certain transmissions, such as the emergency notification of surgery for a brain surgeon, to proceed as normal.

Source:Nano Paint blocks wireless signals

Self replicating machines?

So the only things that can more of themselves are living right? Not really. Scientists at Cornell University have created robots that can pick up parts and make more of themselves. It is a process called self-replication and the blocks look like Legos except that one set will pick up individual blocks and make a copy of itself. The robots are pretty simple and do make more of themselves really fast “The four-module robot was able to construct a replica in 2.5 minutes by lifting and assembling cubes from the feeding locations,” said Hod Lipson, the scientist who headed the team. But it shows it can be done and imagine the possibilities.

So the only things that can more of themselves are living right? Not really. Scientists at Cornell University have created robots that can pick up parts and make more of themselves. It is a process called self-replication and the blocks look like Legos except that one set will pick up individual blocks and make a copy of itself. The robots are pretty simple and do make more of themselves really fast “The four-module robot was able to construct a replica in 2.5 minutes by lifting and assembling cubes from the feeding locations,” said Hod Lipson, the scientist who headed the team. But it shows it can be done and imagine the possibilities.

Source:Self-replicating robot created

Tiny Microphones Made From Locust Eardrums

Ever wanted to know how the world sounds through the ears of an insect? A team of scientists at the University of Bristol have been exploring the eardrums of locusts and mosquitoes by studying how they respond to different noises. Insect’s eardrums vibrate by only a few nanometers when they detect extremely faint sounds. By using nanotechnology to study how insects hear, we can develop microphones to detect noises that the human ear and modern instruments are not able to sense.

Ever wanted to know how the world sounds through the ears of an insect? A team of scientists at the University of Bristol have been exploring the eardrums of locusts and mosquitoes by studying how they respond to different noises. Insect’s eardrums vibrate by only a few nanometers when they detect extremely faint sounds. By using nanotechnology to study how insects hear, we can develop microphones to detect noises that the human ear and modern instruments are not able to sense.

Source:How a locust’s eardrum could lead to tiny microphones

Human Duracells

Tired of having to carry batteries around with you for all your devices? Scientists at the Georgia Institute of Technology are looking to change all of that by using nanotechnology to turn you into a battery. Zinc oxide nanowires, which are non-toxic and safe for humans, would be implanted into the body. The bending and relaxing of those wires would create electricity. That means that we would be creating electricity just by moving or flexing our muscles. These nanowires are so small they would not impede or constrain people. A nanometer is just one billionth of a meter. A human hair is about 100,000 nanometers thick.

Tired of having to carry batteries around with you for all your devices? Scientists at the Georgia Institute of Technology are looking to change all of that by using nanotechnology to turn you into a battery. Zinc oxide nanowires, which are non-toxic and safe for humans, would be implanted into the body. The bending and relaxing of those wires would create electricity. That means that we would be creating electricity just by moving or flexing our muscles. These nanowires are so small they would not impede or constrain people. A nanometer is just one billionth of a meter. A human hair is about 100,000 nanometers thick.

Source:Nanogenerators could turn you into a battery

Walking Musclebots

You’ve probably heard of robots. But, have you heard of musclebots? Scientists at UCLA have made miniature walking machines out of rat heart muscles. Each time the muscle contracts and relaxes, the musclebot takes a step. To make this tiny muscle machines, scientists grow a thin film of heart muscle right on the nanobot using nanotechnology fabrication techniques. In the future, these musclebots could be used to deliver drugs or building other tuny machines.

You’ve probably heard of robots. But, have you heard of musclebots? Scientists at UCLA have made miniature walking machines out of rat heart muscles. Each time the muscle contracts and relaxes, the musclebot takes a step. To make this tiny muscle machines, scientists grow a thin film of heart muscle right on the nanobot using nanotechnology fabrication techniques. In the future, these musclebots could be used to deliver drugs or building other tuny machines.

Micro Musclebot: Wee walker moves by heart cells’ beats

Nano-Enhanced Washing Machines

If you’ve ever walked down the clothing detergent aisle at the supermarket, you may have had a hard time deciding which brand of detergent would kill the most bacteria or give you the cleanest clothes. Now, Samsung has developed a new washing machine called the Silver Nano Health Systems which shoots nano-sized silver ions into the water. The designers at Samsung claim that this new technology will kill 99.9% of odor-causing bacteria. The silver ions will attack and destroy the cell walls of bacteria, and coats the clothing so that any bacteria coming into contact with the ions will stop reproducing for up to 30 days!

If you’ve ever walked down the clothing detergent aisle at the supermarket, you may have had a hard time deciding which brand of detergent would kill the most bacteria or give you the cleanest clothes. Now, Samsung has developed a new washing machine called the Silver Nano Health Systems which shoots nano-sized silver ions into the water. The designers at Samsung claim that this new technology will kill 99.9% of odor-causing bacteria. The silver ions will attack and destroy the cell walls of bacteria, and coats the clothing so that any bacteria coming into contact with the ions will stop reproducing for up to 30 days!

Source:Nano washing machine heading to the U.K.

DNA machines

Ever think about taking your DNA out for a walk? Well not exactly taking YOUR DNA out for a walk but scientists have made DNA molecules that can walk. It turns out that DNA is a pretty interesting molecule and you can make all sorts of shapes. You can make circles, you can also make DNA that is shaped like a ‘Y’. But you can also make DNA that will move from one place to another by designing the sequence so that it grabs on to one strand of DNA and then another. Kind of like climbing hand over hand on a set of monkey bars, except these walkers are only a few nanometers in size. There are lots of tiny machines found in nature, machines that help move stuff around inside of a cell. They are all pretty simple and the challenge for nanotechnology is make machines that can do some serious work. Source:DNA machines take a walk

Ever think about taking your DNA out for a walk? Well not exactly taking YOUR DNA out for a walk but scientists have made DNA molecules that can walk. It turns out that DNA is a pretty interesting molecule and you can make all sorts of shapes. You can make circles, you can also make DNA that is shaped like a ‘Y’. But you can also make DNA that will move from one place to another by designing the sequence so that it grabs on to one strand of DNA and then another. Kind of like climbing hand over hand on a set of monkey bars, except these walkers are only a few nanometers in size. There are lots of tiny machines found in nature, machines that help move stuff around inside of a cell. They are all pretty simple and the challenge for nanotechnology is make machines that can do some serious work. Source:DNA machines take a walk

Can scientists read your mind?

No, not yet — don’t worry! But they’re working on it — and a recent study showed that they can tell at least some things by reading your brain waves. They gave a group of study subjects two different colored patterns to look at, and used a technique called MRI (Magnetic Resonance Imaging) to take a sort of picture of brain activity when the subjects looked at the red and the blue patterns. They discovered that once they had a picture of brain activity for a particular color, they could then use that information to “guess” which color a person was looking at without knowing beforehand. What this shows is that it is possible to get at least some small picture of what someone is thinking, just by studying their brain waves. It’s a long way away from having any kind of machine that can read all of your thoughts, but maybe someday it won’t be unusual at all!

No, not yet — don’t worry! But they’re working on it — and a recent study showed that they can tell at least some things by reading your brain waves. They gave a group of study subjects two different colored patterns to look at, and used a technique called MRI (Magnetic Resonance Imaging) to take a sort of picture of brain activity when the subjects looked at the red and the blue patterns. They discovered that once they had a picture of brain activity for a particular color, they could then use that information to “guess” which color a person was looking at without knowing beforehand. What this shows is that it is possible to get at least some small picture of what someone is thinking, just by studying their brain waves. It’s a long way away from having any kind of machine that can read all of your thoughts, but maybe someday it won’t be unusual at all!

Source:Thoughts read’ via brain scans

Nanoparticles can make paper waterproof

Have you ever put a piece of paper in water and let it sit? It doesn’t last long! Well, a company called Ecology Coatings has accidentally hit upon a way to make paper waterproof — and still writeable! The company makes a special kind of paper coating enhanced with nanoparticles, that helps paper dry faster when exposed to ultraviolet light. One day the researchers discovered that by embedding the coating actually inside the paper instead of surrounding it on the outside, the paper became waterproof — but without changing the texture of it and amking it difficult to write on, as other waterproofing methods usually do. This paper and its special nanoparticle secret sauce could eventually be used to make shipping labels and other paper products that need to be protected from the weather. You could let this paper soak in water all night long, and still be able to write on it in the morning!

Have you ever put a piece of paper in water and let it sit? It doesn’t last long! Well, a company called Ecology Coatings has accidentally hit upon a way to make paper waterproof — and still writeable! The company makes a special kind of paper coating enhanced with nanoparticles, that helps paper dry faster when exposed to ultraviolet light. One day the researchers discovered that by embedding the coating actually inside the paper instead of surrounding it on the outside, the paper became waterproof — but without changing the texture of it and amking it difficult to write on, as other waterproofing methods usually do. This paper and its special nanoparticle secret sauce could eventually be used to make shipping labels and other paper products that need to be protected from the weather. You could let this paper soak in water all night long, and still be able to write on it in the morning!